Condensate temperature can be 180 f saturated pure steam is often at pressures of 30 60 psig temperatures between 274 307 f saturated plant steam is often at pressures around 150 psig temperature of 366 f superheated steam can be at much higher temperatures serious injuries including burns and death are possible.

Clean steam condensate cooler.

Chemical and microbial contaminants can enter steam systems in a variety of ways and in the design of clean steam systems this must be avoided.

Spirax sarco stainless steel sample coolers allows you to sample boiler water safely and accurately.

Cemline blow down condensate coolers are designed to receive blow down from a steam boiler flash the blow down to steam and cool the condensate going to drain.

Pathways for contamination include leakage air being piulled into the system and grow through from a contaminated external environment.

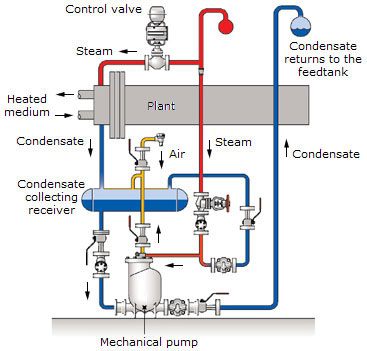

Clean steam condensate and heat recovery systems.

Note the nice insulation job however.

This is probably keeping the problem from being much worse.

We use cookies to give you the best experience on our website.

With information found on the sample cooler inquiry questionnaire a sample cooler can be provided for applications such as steam boiler water chemical processes and others in high pressure and high temperature ranges.

If you continue without changing your cookie settings we assume that you consent to our use of cookies on this device.

Armstrong s condensate cooler mixes hot condensate or hot water with a cold water supply to reduce the temperature to acceptable drain temperatures as required by city and state codes.

High water cut off in some unusual situations it is possible for the feedwater to fail which could cause the unfired steam generator to fill with water and flood the entire system.

The condensate flows from the p trap to a condensate pump or to a drain cooler and finally is wasted down the drain.

This steam trap is therefore acting mostly as a steam cooler wasting steam from the steam main.

Condensate should always be drained from the bottom of the steam line in low sections of pipe and at changes in direction such as a 90 degree turn.

Clean steam must be free of contaminants at the point of use.

Armstrong cc 5 cc 12 cc 25 and cc 40 condensate coolers.

Ssc20 sanitary sample cooler.

Sample coolers are used to cool fluids or vapors to a point they can be safely handled for collection and analysis.

Sc20 sample coolers and systems.